CNC Router Projects From Home

If you have a CNC router in your workshop, then you have a world of possibilities right at your fingertips. Before CNC technology became commonplace, building wood furniture would take tens to hundreds of hours, a varying amount of tools, and a group of skilled craftsmen.

Consistently making furniture wasn’t sustainable in the long run, but a CNC router can cut down the amount of time spent making products that were once only possible by a steady hand.

What is a CNC Router?

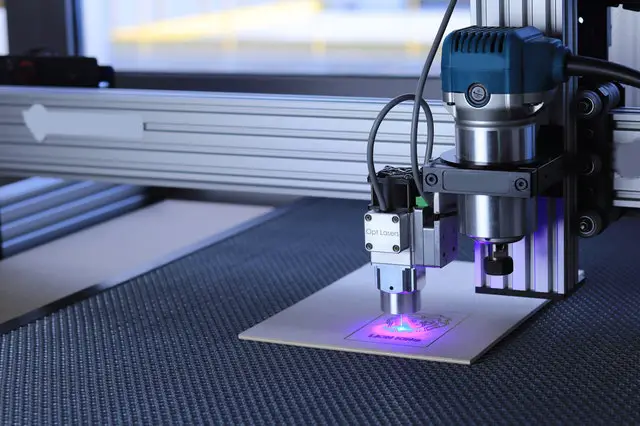

CNC (Computer Numerical Control) routers are computer-controlled cutting machines that use a power tool router to create projects. By using CAM (Computer-Aided Manufacturing) programs, a user can create 2D or 3D models that “print” or cut patterns and shapes in specific materials.

As the digital fabrication industry continues to grow rapidly, DIYers and furniture companies are using CNC routers to build products. However, some new industrial machines are expensive.

Hobbyists or small business owners can purchase a used CNC router to start making full-sized furniture, signs, and more. Keep in mind that your CNC router isn’t limited to wood, although it is the most popular material option. Plastics, glass, and steel can also be cut with a CNC router.

Nowadays, CNC machining aluminum is growing in popularity. It allows you to create fantastic components, provided you select the most suitable aluminum alloy for your project.

How to Find the Perfect CNC Machine for Furniture

CNC routers are ideal for woodworking because they offer precision and additional features that make building furniture a breeze. Here are some features you’ll need to set up your router.

- 4040-XE CNC Router uses 300W spindle and NEMA23 stepper motors, which are more powerful and efficient. Max moving speed is 2000mm/min and spindle speed range is 0~10000.

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

CNC Machine Processors

Most CNC machines will come with three axes (X, Y, and Z-axis) support. However, CNC routers should have 4-axis support for the added A-axis. The A-axis allows the spindle to move left and right to process three surfaces concurrently to achieve 3D and plane engraving.

Rotary axis CNC routers are required to process four surfaces simultaneously. Rotary axis machines can create accents and decorative patterns on cylindrical surfaces with ease.

CNC Machine Motors

There are two motors found on CNC tools: servo and stepper motors.

Servo motors can tolerate high speeds and cut wood precisely without overloading the machine. It’s steady, quiet, and fast, which is ideal for intricate patterns and high productivity.

Stepper motors are more affordable and work for plane engraving. They’re considered “starter motors” because they’re dependable, easy to control, and can handle most projects.

If you’re using your CNC router excessively, a servo motor is what you’re looking for. If you’re a casual DIYer or a small business, a stepper motor will work until you start upping production.

CNC Machine Spindles

Spindles can be water-cooled or air-cooled. Water-cooled spindles are ideal for fast-moving spindles that operate with a stepper motor, while air-cooled spindles are economical and easy to maintain. Only use water-cooled spindles if you need precision and a long-lasting product.

CNC Machine Drives

Screw drive and rack drive systems are common transmission drive systems found in CNC router machines. The drive is responsible for providing automation and precise motion control.

The screw drive is a more basic system that doesn’t offer a lot of speed controls. Its short tool life won’t make it ideal for large projects, but DIYers will prefer them for small woodworking designs because they’re cost-effective. Screw drives will constantly need tightening to work.

Rack drives are accurate, offer multiple configurations, and can handle several projects. They’re fast, last longer, and are expensive, but you can use rack drives on laser modules for deeper engraving depth. Small-to-large businesses will need rack drives to keep up with production.

Table Bed and Size

Router tables are either aluminum or vacuum. Aluminum tables require you to clamp pieces down, which work for oddly-shaped or cylindrical projects. Vacuum tables use suction to keep materials on top of the machine without shaking them, which is great for precise engraving.

Small machines, called “desktop” or “mini” CNC routers, are great for DIYers who make a few projects per year, but large, industrial machines are best for businesses or corporations.

How to Set Up Your Workstation for Furniture Building

An industrial-sized CNC router needs enough clearance for an average-sized person to walk around it. Specific clearance instructions are found in the machine’s manual.

Desk-sized or mini CNC machines don’t require as much clearance, but if you’re putting one on top of a table, you’ll need a surface that can withstand shaking, the machine’s weight, and the material’s weight. Small CNC routers can weigh anywhere between 100-300 pounds.

All CNC routers come with software you’ll need to connect to the hardware. You’ll need to plug in your computer and the CNC machine to an outlet. To connect the CNC machine to your computer, use a USB cable and follow the software’s instructions to configure your tool.

We recommend using a shop vac to suck out the sawdust and particles the router is cutting. This will reduce clean-up time and give you a work area that doesn’t damage your lungs.

How to Start Carving Your Furniture Project

The only tool you’ll need to adjust, change, install, and calibrate is the router bit, but once that’s finished, you can start making your project. Most CNC routers come with preloaded furniture kits, but if you want to create something else, you can load files into your CAM program.

When you hit start, your CNC router should start creating your piece. If there’s a problem, your CNC program will help you troubleshoot. The time it takes for your machine to cut your project depends on the furniture’s complexity and size as well as the machine’s quality.

Most CNC routers won’t cut your project all the way through, so you’ll need a utility knife to remove large chunks of wood or tabs. You’ll need to sand down and smooth out your project.

Unless you plan to nail or glue your furniture together, we recommend finding files that use tabs to connect each piece. Not only will you use fewer supplies, but you’ll be able to fit your furniture together like a puzzle. This makes the project less complicated and time-consuming.

How to Create Your Own Furniture Projects

If you’re interested in creating furniture projects that don’t utilize pre-built CAM files, you’ll need to learn how to program. There are several online classes, video tutorials, and forums that can help you make unique pieces of furniture, from shelves to cabinets to coffee tables.

Whether you decide to hire a programmer, learn to program yourself, or use ready-made CAM files, we recommend taking a hybrid approach to furniture building for sophisticated projects.

Hybrid woodworking techniques combine power and hand tools with a CNC router.

A high-quality shaping jigsaw is actually faster, safer, and more efficient than most CNC routers. Rough cutting is difficult to replicate with a CNC machine but simple to do with a saw. There are hundreds of ways you could use both techniques to make woodworking more productive.

Signing Off

Although building furniture with a CNC router can feel more complicated than creating the same product by hand, CNC machines allow DIYers and businesses to make more with less.

Like any skill, learning how to create furniture will take some getting used to, but once you’ve gotten the kinks out, you’ll be able to effortlessly “print” out unique pieces.

If this is not wetting your appetite then you may want to consider a simple option of recycling furniture. This is a much used route and very popular for upcycling old furniture.